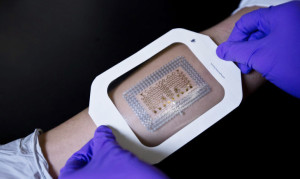

Engineers have figured out how to mass produce an inexpensive wearable patch that continuously monitors vital signs for health and performance tracking. They believe the tattoo-like device has the potential to outperform more traditional tools like cardiac monitors.

The breakthrough is a repeatable “cut-and-paste” method that cuts manufacturing time from several days to only 20 minutes. The new method is compatible with roll-to-roll manufacturing—an existing method for creating devices in bulk using a roll of flexible plastic and a processing machine.

Reliable, ultrathin wearable electronic devices that stick to the skin like a temporary tattoo are a relatively new innovation. The devices have the ability to pick up and transmit the human body’s vital signals, tracking heart rate, hydration level, muscle movement, temperature, and brain activity.

Although it is a promising invention, a lengthy, tedious, and costly production process has until now hampered these wearables’ potential.

“One of the most attractive aspects of epidermal electronics is their ability to be disposable,” says Nanshu Lu, assistant professor in the Cockrell School of Engineering at the University of Texas at Austin. “If you can make them inexpensively, say for $1, then more people will be able to use them more frequently. This will open the door for a number of mobile medical applications and beyond.”

Described in the journal Advanced Materials, the new method is the first dry and portable process for producing these electronics, which, unlike the current method, doesn’t require a clean room, wafers, and other expensive resources and equipment. Instead, the technique relies on freeform manufacturing, which is similar in scope to 3D-printing but different in that material is removed instead of added.

The two-step process starts with inexpensive, pre-fabricated, industrial-quality metal deposited on polymer sheets. First, an electronic mechanical cutter is used to form patterns on the metal-polymer sheets. Then, after removing excessive areas, the electronics are printed onto any polymer adhesives, including temporary tattoo films. The cutter is programmable so the size of the patch and pattern can be easily customized.

Deji Akinwande, associate professor and materials expert, says he believes the method can be transferred to roll-to-roll manufacturing.

“These initial prototype patches can be adapted to roll-to-roll manufacturing that can reduce the cost significantly for mass production. In this light, Lu’s invention represents a major advancement for the mobile health industry.”

After producing the cut-and-pasted patches, the researchers tested them and discovered they picked up body signals that were stronger than those taken by existing medical devices, including an ECG/EKG, a tool used to assess the electrical and muscular function of the heart. The patch also conforms almost perfectly to the skin, minimizing motion-induced false signals or errors.

The wearable patches are so sensitive they may be worn to more easily maneuver a prosthetic hand or limb using muscle signals, Lu says. But for, now, “We are trying to add more types of sensors including blood pressure and oxygen saturation monitors to the low-cost patch.”

The National Science Foundation funded the work.

Source: University of Texas at Austin and Futurity.org